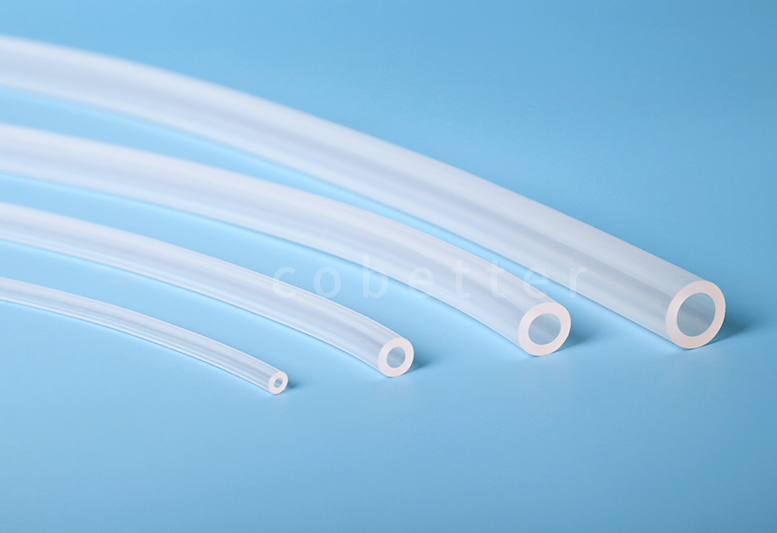

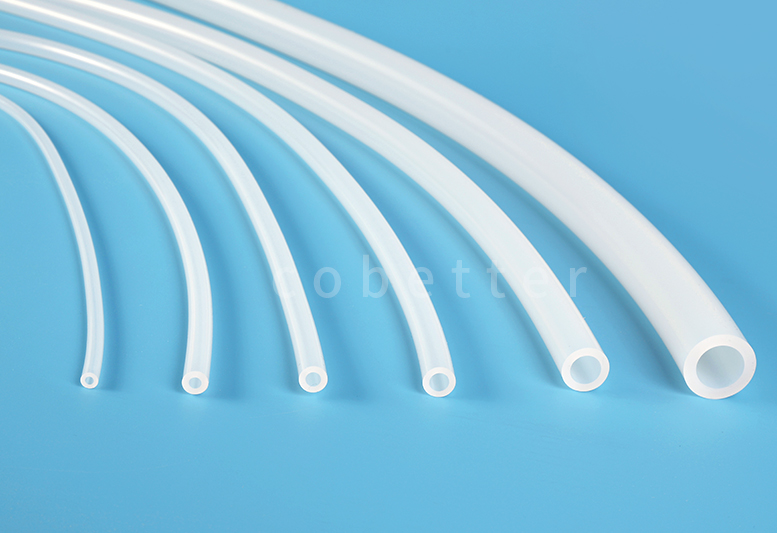

Lifemeta™ STTシリコン(Pt)チューブ

Cobetter Lifemeta™ STT シリコン(Pt)チューブは、効率的な流体移送のために設計されています。この製品は、押し出し装置と成形ツールによって高純度の医療グレードの原材料を使用して製造されており、極端な温度、さまざまな酸、アルカリ塩、有機溶剤、放射線に耐えることができ、また優れた弾力性と耐引裂性も備えているため、蠕動ポンプでの使用に適しています。Lifemeta™ STTチューブは半透明で内面が滑らかであり、低吸着アプリケーションに信頼性の高いソリューションを提供します。

推奨の業界アプリケーション:

お見積りのお問い合わせ

概要

特徴

- 高純度の医療グレードの原材料

- 製造工程の継続的な監視

- 滑らかな内面、半透明のチューブ

- さまざまな酸、アルカリ、塩、有機溶剤に耐性があります

- チューブの強靭性を保証する優れた引張強度

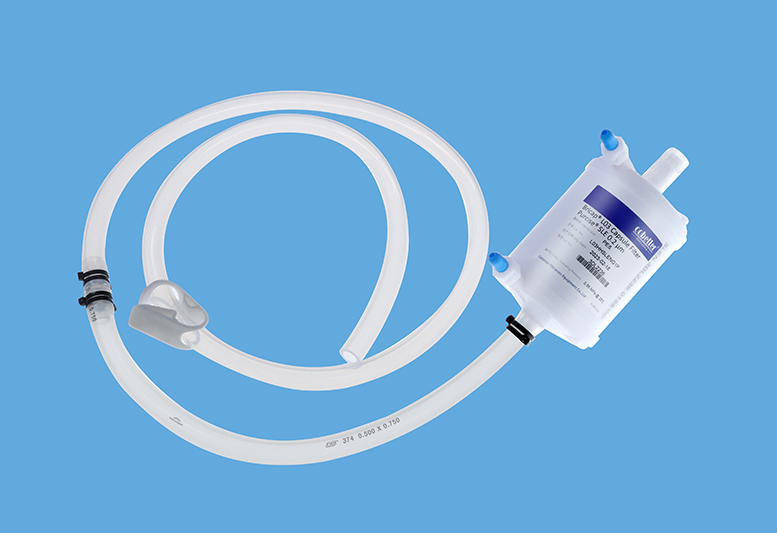

アプリケーション

- 培養培地および緩衝液の調製

- バイオリアクターおよび培養システムへの供給液の供給

- ベース液の上流および下流への移送

- シングルユースアセンブリシステムの統合

- ラボでの流体移送

- 食品加工

製品性能

| Tubing Series | Lifemeta™ STT |

| Material | Pt-cured Silicone |

| Durometer Hardness (Shore A) | 60±5 |

| Appearance | Translucent |

| Aseptic Sealing and Welding | No |

| Peristaltic Pump Life | Fair |

| Min. Temperature | -59.8℉ | -51℃ |

| Max. Temperature | 449.6℉ | 232℃ |

| Gamma Stability (max. 50 kGy) | √ |

| Sterilization Methods | Autoclave Gamma irradiation |

| Validation Guide | √ |

| Packaging | Double layer PE bag packaging |

| Recommended usage | Culture media and buffers Preparation Fermentation/CultivationPurification |

Regulatory Compliance

| Particulate Matter | Particulate matter in the product eluent meets the requirements in USP <788> for large volume parenterals. |

| Bacterial Endotoxin | Aqueous extraction contains < 0.25 EU/mL as determined by Amebocyte Lysate, USP <85>. |

| USP <87> Cytotoxicity | Meet the requirement of USP <87> In Vitro Biological Reactivity Test. |

| USP <88> Biological Reactivity | Meet the criteria of the USP <88> Biological Reactivity Test for Class VI plastics. |

| ISO 10993-4 | Meet the requirement of ISO 10993-4 In Vitro Hemolytic Test. |

| Indirect Food Additive | The fluid contact component materials meet the FDA Indirect Food Additive requirements cited in 21 CFR 177–182. |

| Animal Derivative Content | Products do not contain animal derived components and are free from TSE risk. |

| Quality Assurance | These products are manufactured in a facility which adheres to ISO 9001:2015 Practices. |

Sterilization Methods

| Gamma Irradiation | >Can be gamma irradiated at 25-45 kGy in sterile package and can not be re-sterilized. |

| Autoclave | Can be autoclaved 25 cycles for 30 minutes at 121 °C. |

Physical characteristics

| Item | Value | Procedure |

| Durometer Hardness (Shore A) | 60 ± 5 | ASTM D2240 |

| Burst Strength | 0.4-0.9 MPa | ASTM D380 |

| Tensile Strength | 7.05-8.96 MPa | ASTM D412 |

| Elongation at Break | 378-443% | ASTM D412 |

| Vacuum Resistance | > 30 kPa | ISO 7233: 2016 |

| Temperature Range | -51-232 °C |

Note: Please refer to the validation guide document for detailed test methods and results.

ご注文情報

| Part Number | I.D. | O.D. | Wall Thickness | Tube Number | Packaging* | Qty(m/pk) | |||

| In. | mm. | In. | mm. | In. | mm. | ||||

| STT0816150N | 1/32" | 0.8 | 5/32" | 4.0 | 1/16" | 1.6 | 13# | Non-sterile | 15 |

| STT1216150N | 3/64" | 1.2 | 11/64" | 4.4 | 1/16" | 1.6 | / | Non-sterile | 15 |

| STT1616150N | 1/16" | 1.6 | 3/16" | 4.8 | 1/16" | 1.6 | 14# | Non-sterile | 15 |

| STT1624150N | 1/16" | 1.6 | 1/4" | 6.4 | 3/32" | 2.4 | 119# | Non-sterile | 15 |

| STT2416150N | 3/32" | 2.4 | 7/32" | 5.6 | 1/16" | 1.6 | 19# | Non-sterile | 15 |

| STT2424150N | 3/32" | 2.4 | 9/32" | 7.1 | 3/32" | 2.4 | / | Non-sterile | 15 |

| STT3060150N | / | 3.0 | / | 6.0 | / | 1.5 | / | Non-sterile | 15 |

| STT3224150N | 1/8" | 3.2 | 5/16" | 8.0 | 3/32" | 2.4 | 120# | Non-sterile | 15 |

| STTL150N | 1/8" | 3.2 | 1/4" | 6.4 | 1/16" | 1.6 | 16# | Non-sterile | 15 |

| STT25150N | 3/16" | 4.8 | 5/16" | 8.0 | 1/16" | 1.6 | 25# | Non-sterile | 15 |

| STT15150N | 3/16" | 4.8 | 3/8" | 9.6 | 3/32" | 2.4 | 15# | Non-sterile | 15 |

| STT4832150N | 3/16" | 4.8 | 7/16" | 11.2 | 1/8" | 3.2 | / | Non-sterile | 15 |

| STT17150N | 1/4" | 6.4 | 3/8" | 9.6 | 1/16" | 1.6 | 17# | Non-sterile | 15 |

| STTR150N | 1/4" | 6.4 | 7/16" | 11.2 | 3/32" | 2.4 | 24# | Non-sterile | 15 |

| STT26150N | 1/4" | 6.4 | 1/2" | 12.7 | 1/8" | 3.2 | 26# | Non-sterile | 15 |

| STT35150N | 5/16" | 8.0 | 1/2" | 12.7 | 3/32" | 2.4 | 35# | Non-sterile | 15 |

| STT36150N | 3/8" | 9.6 | 9/16" | 14.4 | 3/32" | 2.4 | 36# | Non-sterile | 15 |

| STTY150N | 3/8" | 9.6 | 5/8" | 15.9 | 1/8" | 3.2 | 73# | Non-sterile | 15 |

| STTH150N | 1/2" | 12.7 | 3/4" | 19.1 | 1/8" | 3.2 | 82# | Non-sterile | 15 |

| STTE150N | 1/2" | 12.7 | 11/16" | 17.5 | 3/32" | 2.4 | / | Non-sterile | 15 |

| STTX150N | 5/8" | 15.9 | 7/8" | 22.2 | 1/8" | 3.2 | 184# | Non-sterile | 15 |

| STTN150N | 3/4" | 19.1 | 1" | 25.4 | 1/8" | 3.2 | 90# | Non-sterile | 15 |

| STTM100N | 3/4" | 19.1 | 1-1/8" | 28.6 | 3/16" | 4.8 | 191# | Non-sterile | 10 |

| STTD050N | 1" | 25.4 | 1-3/8" | 34.9 | 3/16" | 4.8 | 92# | Non-sterile | 10 |

* *Packaging: This product is available in sterile or non-sterile packaging. The sterilization method for sterile products is gamma irradiation, and the irradiation dose is 25~45 kGy.

eShop

eShop